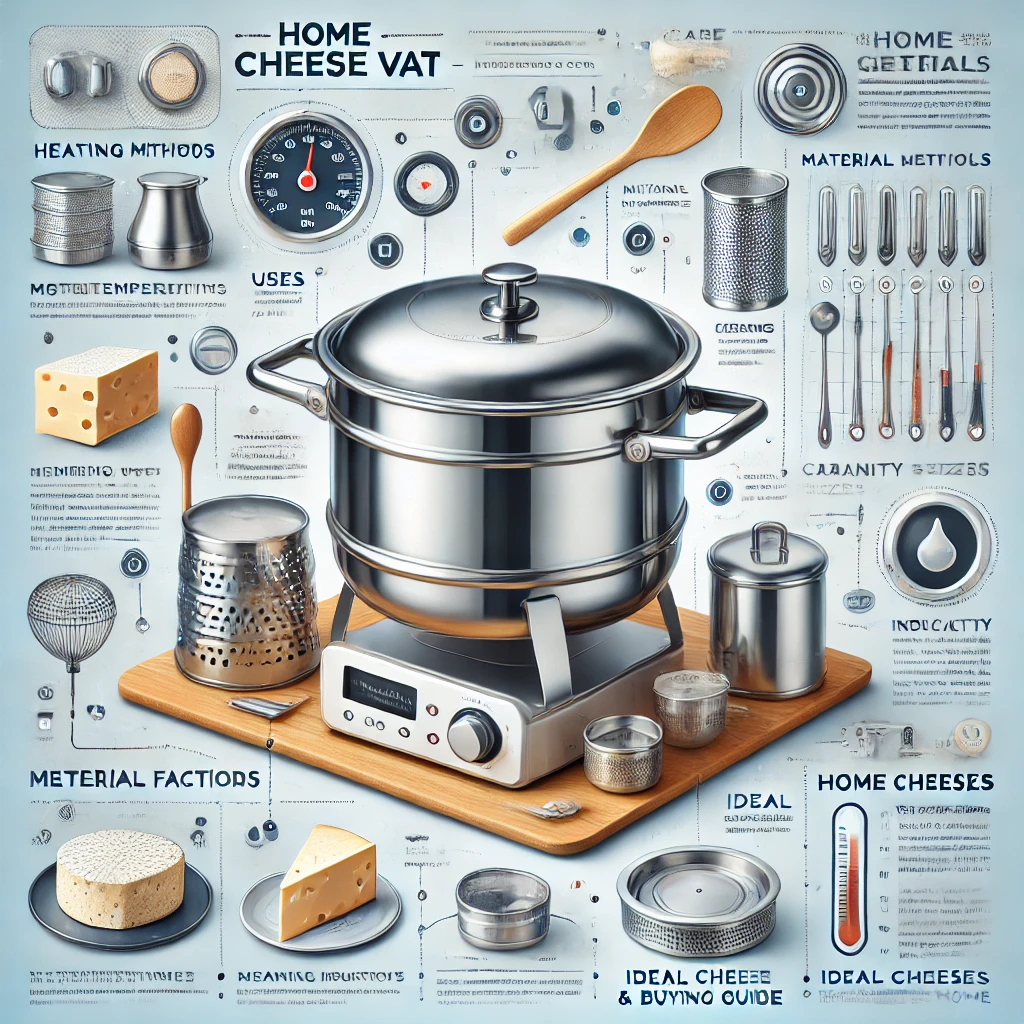

Crafting cheese at home has grown from a niche hobby to a refined kitchen craft, and at the center of that evolution is the home cheese vat. Whether you are making mozzarella once a month, culturing feta weekly, or aging farmhouse cheddar, the vat is the vessel where curd magic begins—heat, coagulation, acidification, whey separation, and curd stability.

Unlike pots used casually in cooking, a cheese vat is calibrated for thermo-sensitive milk handling, ensuring precision and hygiene. For home cheesemakers, it brings professional dairy control without industrial scale.

🧀 What Is a Home Cheese Vat?

A home cheese vat is a specialized milk-handling container designed to heat, hold, and culture milk at specific temperatures without scorching, curd tearing, or bacterial contamination.

It acts as a micro-dairy unit, built to maintain thermal accuracy, safety, and even heat distribution.

Core Functions

| Function | Purpose |

|---|---|

| Heating milk | controlled temperature for pasteurization or culturing |

| Holding curds | stability during coagulation |

| Cutting & stirring | preserving curd softness |

| Draining whey | clean separation |

| Sanitizing | stainless interior prevents residue |

Home vats range from 5-20 liters, ideal for household batches or farm kitchen production.

⚙️ Why a Cheese Vat Instead of a Pot?

Standard cooking pots are made for boiling, frying, and sautéing—not delicate milk science.

Vat Advantages

-

precise temperature control (±0.5°C)

-

no scorching at bottom

-

smooth stainless interior

-

sanitary welds & dairy-grade alloy

-

gentle heat dispersion preventing curd damage

-

tight lid for fermentation safety

Milk proteins are fragile. Temperature spikes harden curds or weaken structure, altering moisture extraction and aging potential.

🥛 Main Uses of a Home Cheese Vat

| Stage | Role of Vat |

|---|---|

| Pasteurizing | controlled heat at 63–72°C |

| Coagulating | rennet or acid sets curd evenly |

| Cutting curds | intact structure retention |

| Stirring curds | avoids shattering and whey flooding |

| Draining | clean whey channeling |

| Brining (optional) | for soft cheeses |

Cheeses Perfect for Vat Use

-

Mozzarella

-

Feta

-

Gouda

-

Cheddar

-

Tilsit

-

Romano

-

Paneer

-

Ricotta

-

Halloumi

-

Queso fresco

-

Blue cheese types (with controlled temp holds)

🏗 Materials: What Should a Vat Be Made Of?

The material determines hygiene, longevity, and bacterial safety.

Recommended Materials

| Material | Strength | Notes |

|---|---|---|

| Stainless Steel 304 | corrosion-resistant, dairy-safe | most common |

| Stainless Steel 316 | premium anti-corrosion | ideal for heavy salting |

| Food-grade enamel | easy cleaning | avoid chips |

| Copper (rare) | perfect thermal conduction | requires tin lining |

Materials to Avoid

-

aluminum (reacts with acid whey)

-

raw copper (non-lined & oxidizing)

-

low-grade steel (rust risk)

Milk contains lactose and lactic acid—reactive metals compromise flavor and safety.

🧴 Care & Cleaning

Consistent cleaning prevents milk stone, fat film, and bacterial growth.

Daily Cleaning Routine

-

Rinse with lukewarm water immediately after use

-

Add mild dairy-grade detergent

-

Use soft sponge (never abrasive steel pads)

-

Rinse thoroughly

-

Towel-dry to avoid mineral spots

Deep Cleaning (Weekly)

-

Use citric acid solution to dissolve milk stone

-

Rinse and neutralize with warm water

Sanitizing

Before each batch:

-

rinse with hot water at 80–90°C

-

avoid chemical fragrances that affect curd

🔧 Maintenance

-

Inspect welds, seams, and drains for residue

-

Replace silicone gaskets if odor absorbs

-

Keep lid vents clear to avoid microbial buildup

-

Avoid dipping heating coils directly if external heater is attached

Heat System Options

| Type | Precision | Notes |

|---|---|---|

| Built-in electric | highest | integrated thermostat |

| Water jacket (double layer) | gentle & uniform heat | premium version |

| Stove-heated | variable | requires dairy thermometer |

🛍 Buying Guide: How to Choose the Right Vat

Key Considerations

| Feature | Why It Matters |

|---|---|

| Capacity | 10–15L ideal for home artisans |

| Thermostat | prevents overheating |

| Double-jacket heating | professional consistency |

| Stainless grade | 304 or 316 recommended |

| Drain valve | cleaner whey release |

| Smooth welds | hygiene + no curd snagging |

Pricing Range

| Type | Cost |

|---|---|

| Basic stainless pot-style vat | $60–$150 |

| Thermostat-integrated vat | $180–$350 |

| Water-jacket premium | $400–$750 |

🌿 Best Practices

-

never boil milk directly, even in vat

-

keep curd stirring slow; rushing creates grainy cheese

-

maintain steady temperature—cheese dislikes fluctuation

-

clean immediately after draining to avoid whey smell

⭐ Conclusion

A home cheese vat is more than a cooking vessel—it’s the foundation of proper cheesemaking. It gives beginners confidence and artisans precision, allowing milk to be transformed into stable, flavor-balanced, texturally consistent cheese.

From feta to gouda, mozzarella to cheddar, a vat protects curds, controls heat, and ensures sanitary processing. If you are serious about dairy craft, a cheese vat isn’t a luxury—it is the tool that guarantees professional quality in a home environment.

FAQs – Home Cheese Vat

1. Can I use a regular pot instead of a vat?

Yes, but quality and temperature precision will drop significantly.

2. What size is best for beginners?

A 10–12 liter stainless steel vat.

3. How do I reduce scorching risk?

Choose double-jacket heating or use indirect water bath.

4. What’s the safest material?

Food-grade stainless steel (304 or 316).

5. Can I pasteurize milk in a vat?

Yes, with accurate temperature monitoring.