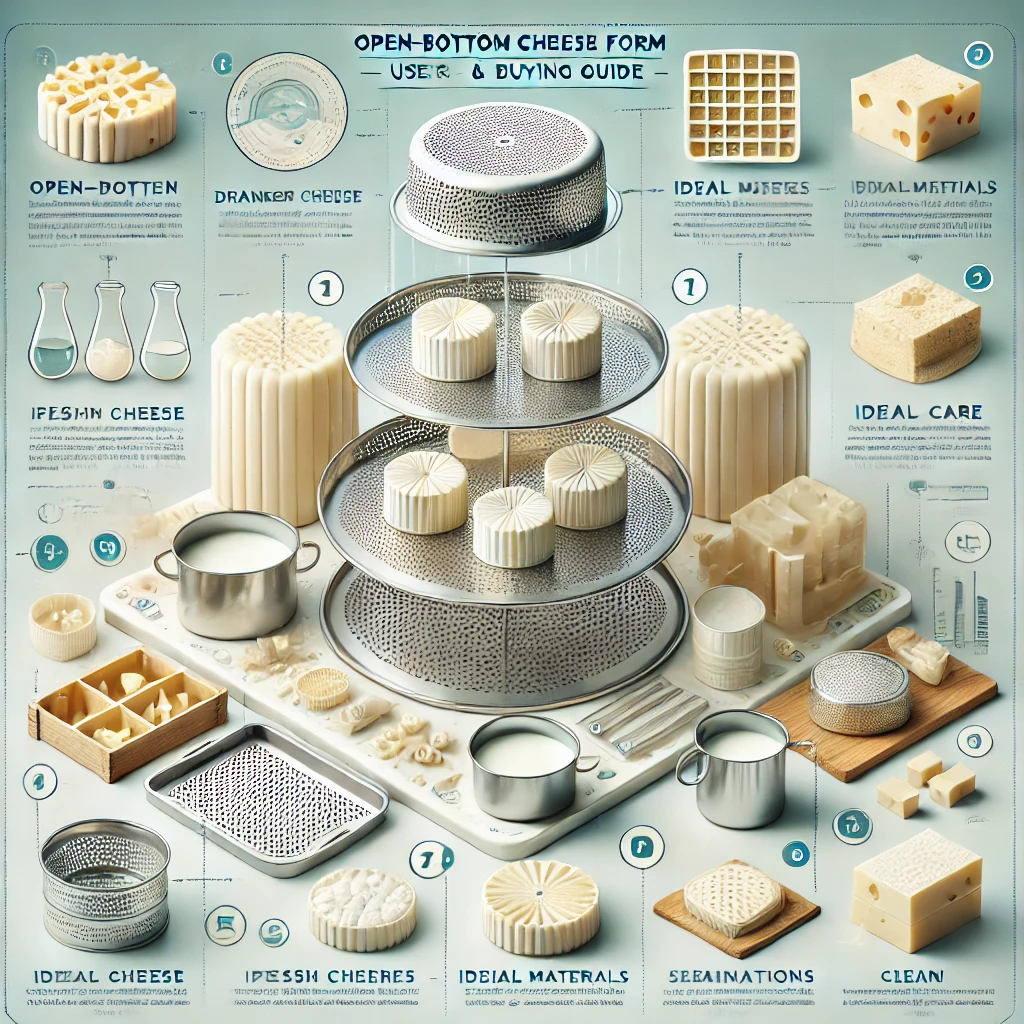

Cheesemaking has existed for thousands of years, evolving from simple cloth draining methods to modern tools that allow home and professional cheesemakers to produce consistent, high-quality cheeses. Among these tools, the open-bottom cheese form—also called an open-bottom mold—plays an essential role. Designed to help shape, drain, and firm curds efficiently, this mold is a must-have for both beginners and artisanal cheesemakers.

This comprehensive guide explores everything you need to know about open-bottom cheese forms, including what they are, how they work, types of materials, best uses, cleaning and care, and tips for choosing the right one.

🧀 What Is an Open-Bottom Cheese Form?

An open-bottom cheese form is a cheese mold that has no base, allowing whey to drain freely through the bottom as well as the sides. Unlike closed-bottom molds that require draining holes only around the sides, open-bottom forms rely on gravity and pressure to help whey escape naturally.

Key Features:

-

Cylindrical or slightly tapered shape

-

Perforated or slotted sides

-

Flat-bottomless design

-

Works with draining mats or cheesecloth

Cheeses Typically Made with This Mold:

-

Soft cheeses

-

Semi-soft cheeses

-

Traditional farm cheeses

-

Washed-curd varieties

-

Fresh cheeses requiring high drainage

The open-bottom form is valued for its efficiency, clean results, and versatile applications.

🧀 How an Open-Bottom Cheese Form Works

The design is simple but effective. The curds are placed into the mold, which is set on:

-

a draining mat

-

a perforated tray

-

a cheesecloth-lined surface

As whey naturally drains downward, gravity and gentle pressing help form the curd into a uniform shape.

Why Use an Open-Bottom Mold?

-

Improves drainage efficiency

-

Reduces risk of trapped whey

-

Produces firmer, cleaner cheese bodies

-

Shortens pressing time

-

Encourages even rind development

Because whey can escape freely, the curds settle more evenly, resulting in a smoother cheese texture.

🧀 Benefits of Using an Open-Bottom Cheese Form

Whether you are a hobbyist or a small-batch artisan, these molds offer valuable advantages.

⭐ 1. Fast and Natural Drainage

The open bottom removes whey quickly, preventing sour or soggy cheese.

⭐ 2. Ideal for Many Cheese Styles

Especially effective for:

-

Swiss-style cheeses

-

Soft goat cheese

-

Halloumi-style fresh cheeses

-

Tomme styles

-

Washed-rind cheeses

⭐ 3. Prevents Whey Pooling

Pooling leads to:

-

uneven textures

-

inconsistencies in acidity

-

off-flavors

Open-bottom molds prevent these issues.

⭐ 4. Easy to Clean

With no base attached, these molds are simpler to scrub and sanitize.

⭐ 5. Efficient for Pressing

Allows uniform downward pressure without resistance from a solid bottom.

🧱 Materials Used in Open-Bottom Cheese Forms

Open-bottom molds are produced using different materials, each with unique properties.

⭐ 1. Food-Grade Plastic

The most common material for modern cheesemakers.

Advantages:

-

lightweight

-

strong and durable

-

dishwasher-safe

-

inexpensive

Best For:

Beginners and everyday cheese production.

⭐ 2. Stainless Steel

Preferred by professional cheesemakers.

Advantages:

-

highly durable

-

resists odors and staining

-

ideal for long-term use

-

easy to sanitize

Best For:

Hard and semi-hard cheese varieties, commercial production.

⭐ 3. Traditional Wood

Less common today, but still used by some artisanal producers.

Advantages:

-

imparts natural microflora

-

authentic texture and flavor profiles

Best For:

Traditional Alpine or farmstead cheeses.

Note:

Wood requires strict cleaning to prevent bacterial growth.

⭐ 4. Silicone-Coated or Hybrid Molds

A newer addition combining structure with flexibility.

Advantages:

-

gentle on delicate curds

-

easy release

-

ideal for soft cheeses

🍽 Cheeses Best Made with an Open-Bottom Mold

This mold is favored worldwide for its ability to shape diverse cheese types.

Popular Cheeses:

-

Tomme-style cheeses

-

Swiss and Alpine cheeses

-

Soft goat cheeses (chèvre, fresh rounds)

-

Halloumi-style slabs

-

Farmhouse cow milk cheeses

-

Ricotta salads and fresh wheels

It provides consistent results across fresh, semi-soft, and lightly pressed cheeses.

🧼 Care & Cleaning of Open-Bottom Cheese Forms

Proper maintenance ensures safety and extends the lifespan of your molds.

⭐ 1. Rinse Immediately After Use

Dried curds cling to surfaces and become difficult to remove.

⭐ 2. Use Hot Water and Mild Soap

Avoid harsh chemicals that can damage plastic or alter cheese flavor.

⭐ 3. Sanitize Before Each Batch

Place in:

-

boiling water (plastic-safe)

-

a food-safe sanitizing solution

-

a dishwasher for plastic molds

⭐ 4. Air Dry Thoroughly

Moisture breeds bacteria—allow the mold to dry completely before storage.

⭐ 5. Avoid Scratching the Surface

Scratches trap bacteria. Use soft brushes, not abrasive scrubbers.

🛒 Buying Guide: Choosing the Right Open-Bottom Cheese Form

Selecting the best mold depends on your skills, cheese style, and workflow.

⭐ 1. Size Matters

Choose based on the volume of curds you typically work with:

-

small (for chèvre, small wheels)

-

medium (for home cheesemaking)

-

large (farmhouse cheeses, commercial batches)

⭐ 2. Check Perforation Pattern

More holes = faster drainage

Fewer holes = slower, controlled drainage

Match the pattern to your cheese style.

⭐ 3. Material Durability

-

Plastic = affordable and beginner-friendly

-

Stainless steel = long-term investment

-

Wood = artisanal use only

⭐ 4. Stability & Reinforcement

A sturdy mold will not warp under pressure, ensuring even cheese shaping.

⭐ 5. Ease of Cleaning

Look for smooth, seamless construction.

⭐ 6. Price vs Quality

Don’t choose the cheapest option—durability matters for long-term cheesemaking.

🌍 Why Open-Bottom Cheese Forms Are Loved by Artisans

Artisans value these molds for their:

-

natural draining action

-

ability to develop beautiful rinds

-

versatility across cheese types

-

compatibility with traditional pressing techniques

They combine historic functionality with modern food safety standards.

⭐ Conclusion

The open-bottom cheese form is a foundational tool in the cheesemaker’s kit. Its efficient draining system, versatile design, and compatibility with various cheese styles make it ideal for both traditional and contemporary cheesemaking. Whether you’re crafting soft goat cheese, farmhouse wheels, or Alpine-style varieties, this mold ensures consistent texture and quality.

By choosing the right material, caring for the mold properly, and understanding its many uses, you can elevate your cheesemaking experience—and produce cheeses that truly stand out.

FAQs – Open-Bottom Cheese Form

1. What is an open-bottom cheese form used for?

It’s used to shape and drain cheese curds efficiently by allowing whey to escape through the bottom and sides.

2. Can I use an open-bottom mold for hard cheeses?

Yes, especially for tomme and semi-hard varieties that require stronger drainage.

3. Are open-bottom cheese forms suitable for beginners?

Absolutely—they are easy to use, clean, and versatile.

4. What material is best for cheesemaking molds?

Food-grade plastic is great for beginners; stainless steel is best for professionals.

5. How do I clean an open-bottom cheese form?

Rinse immediately, wash with hot water and mild soap, sanitize, and allow to fully air dry.