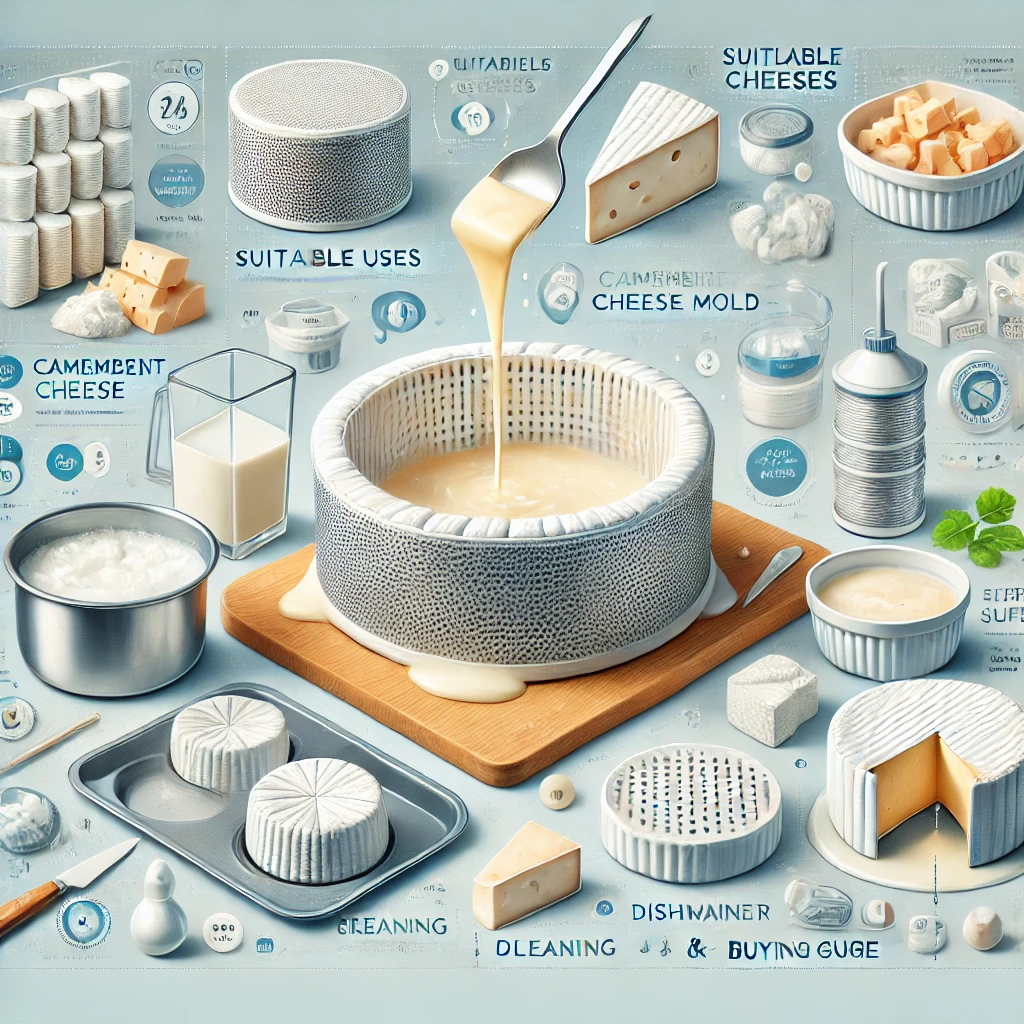

Camembert is one of the most recognizable soft cheeses in the world, celebrated for its creamy center and delicate white rind. While milk quality and cultures often get the spotlight, one essential tool quietly shapes the success of this cheese—the Camembert cheese mold. Without the right mold, achieving the classic shape, texture, and even ripening becomes extremely challenging.

This in-depth guide explains Camembert cheese mold uses, materials, proper care, and how to choose the best one, whether you are a beginner home cheesemaker or an experienced artisan producer.

What Is a Camembert Cheese Mold?

A Camembert cheese mold is a cylindrical, open-ended container designed specifically for soft, bloomy-rind cheeses. Unlike hard cheese molds, it does not require pressing. Instead, it allows whey to drain naturally through side perforations using gravity alone.

The mold defines:

-

The traditional Camembert wheel shape

-

Consistent thickness and diameter

-

Proper moisture retention for rind development

This gentle shaping process is key to Camembert’s creamy interior and even ripening.

Why Camembert Cheese Molds Matter

Ensures Proper Drainage

Camembert curds are fragile and high in moisture. The mold’s holes allow whey to escape slowly, preventing collapse or excessive dryness.

Maintains Authentic Shape

The iconic low, round profile of Camembert depends entirely on the mold’s dimensions.

Supports Healthy White Rind Growth

Balanced airflow around the cheese encourages even growth of Penicillium camemberti, the mold responsible for Camembert’s white rind.

Common Uses of Camembert Cheese Molds

Although designed for Camembert, these molds are versatile and widely used for:

-

Camembert and Camembert-style cheeses

-

Small Brie wheels

-

Goat milk bloomy-rind cheeses

-

Experimental soft cheeses

Many cheesemakers keep multiple molds to produce different batch sizes.

Materials Used in Camembert Cheese Molds

Food-Grade Plastic (Most Popular)

Most modern Camembert molds are made from BPA-free, food-safe plastic, usually polypropylene.

Benefits:

-

Lightweight and affordable

-

Resistant to moisture and acids

-

Easy to clean and sanitize

-

Long-lasting for repeated use

Plastic molds are ideal for both home and small-scale commercial cheesemaking.

Stainless Steel (Professional Option)

Less common but sometimes used in professional dairies.

Advantages:

-

Extremely durable

-

Excellent hygiene

-

Resistant to staining and odor

Drawbacks:

-

High cost

-

Heavier and less beginner-friendly

Traditional Materials (Historical)

Older methods used ceramic or wooden forms, but these are not recommended today due to sanitation risks and inconsistent drainage.

Standard Sizes and Dimensions

Choosing the correct mold size directly affects texture and ripening.

Classic Camembert Mold

-

Diameter: 10–11 cm (4–4.5 inches)

-

Height: 7–8 cm (2.5–3 inches)

Alternative Sizes

-

Mini molds for small batches or tasting cheeses

-

Taller molds for thicker, slower-ripening wheels

Always match mold size with milk quantity for best results.

How to Use a Camembert Cheese Mold

Step 1: Sanitize the Mold

Clean and sanitize thoroughly before use to avoid contamination.

Step 2: Fill with Curds

Ladle curds gently into the mold in stages. Allow whey to drain between additions.

Step 3: Gravity Drainage

Do not press. Let gravity remove whey naturally.

Step 4: Flip the Cheese

Flip the cheese periodically during draining to maintain shape and even moisture.

Step 5: Unmold and Salt

Once firm enough, remove the cheese, salt it evenly, and prepare for aging.

Caring for Camembert Cheese Molds

Cleaning

-

Rinse immediately after use

-

Wash with warm water and mild detergent

-

Avoid harsh chemicals or scented soaps

Sanitizing

-

Use food-safe sanitizer or hot water

-

Never use boiling water on plastic molds

Drying and Storage

-

Air-dry completely

-

Store in a clean, dry place away from contaminants

Proper care prevents unwanted mold growth and extends mold lifespan.

Common Mistakes to Avoid

-

Using molds without drainage holes

-

Applying pressure to the curds

-

Poor sanitation practices

-

Choosing the wrong mold size

-

Storing molds while still damp

Avoiding these errors ensures consistent, high-quality cheese.

Buying Guide: How to Choose the Best Camembert Cheese Mold

1. Food Safety Certification

Ensure the mold is food-grade and BPA-free.

2. Hole Pattern and Drainage

Uniform, evenly spaced holes improve whey release and rind development.

3. Smooth Interior Walls

Smooth surfaces prevent curd damage and make cleaning easier.

4. Durability

Thicker plastic molds resist cracking and warping over time.

5. Reputable Supplier

Buy from trusted cheesemaking equipment suppliers rather than generic kitchenware brands.

Price and Availability

Camembert cheese molds are widely available and reasonably priced:

-

Entry-level molds: affordable for beginners

-

Professional molds: higher cost, longer lifespan

They are easy to find through online cheesemaking stores and dairy supply shops.

Who Should Use a Camembert Cheese Mold?

These molds are ideal for:

-

Home cheesemakers

-

Artisan cheese producers

-

Culinary schools

-

Food experimenters and hobbyists

They are beginner-friendly while still meeting professional standards.

Sustainability and Reuse

Reusable Camembert molds reduce waste and support sustainable cheesemaking. With proper care, a single mold can last for many years, making it an eco-friendly investment.

Conclusion

The Camembert cheese mold is a foundational tool in soft cheese production. It controls shape, drainage, moisture balance, and rind development—factors that directly influence flavor and texture. Choosing the right mold material, size, and design, combined with proper care, allows cheesemakers to consistently produce authentic, high-quality Camembert.

Whether you are just starting your cheesemaking journey or refining your technique, investing in a quality Camembert cheese mold is essential for success.

Frequently Asked Questions (FAQ)

What is a Camembert cheese mold used for?

It shapes the cheese and allows gentle whey drainage without pressing.

Can Camembert cheese molds be reused?

Yes, food-grade molds are reusable for many years with proper cleaning.

Is pressing required when using a Camembert mold?

No, Camembert relies on gravity drainage only.

What material is best for Camembert cheese molds?

Food-grade plastic is the most practical and widely used option.

Are Camembert and Brie molds interchangeable?

They are similar, but Camembert molds are usually smaller and taller.