Precision, clean cuts, and professional slicing define artisanal cheesemaking—and at the center of that craft lies the heavy-duty cheese wire. Unlike basic kitchen blades or standard slicers, a cheese wire is engineered to glide through dense, aged wheels, high-fat blocks, and delicate soft rinds without crushing or crumbling the structure of the cheese.

For cheesemakers, deli operators, charcuterie experts, and serious home artisans, a heavy-duty cheese wire is not just a tool—it is the difference between uniform, hygienic slicing and messy fragmentation.

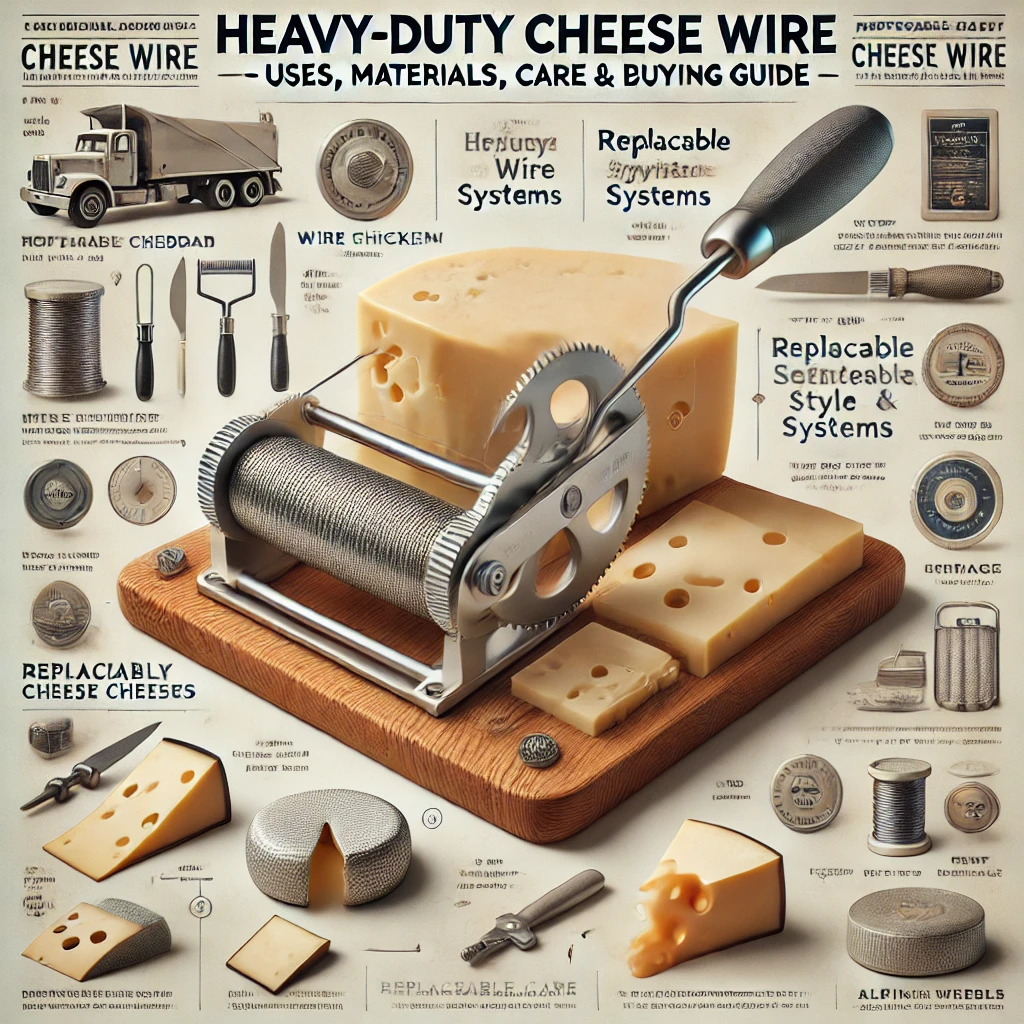

🧀 What Is a Heavy-Duty Cheese Wire?

A heavy-duty cheese wire is a high-tension cutting cable designed to slice cheese using pressure and tensile strength instead of a sharpened blade. It ensures:

-

zero compression

-

smooth cut surfaces

-

no flavor contamination

-

clean edges ideal for plating or packaging

It is especially necessary for:

-

aged hard wheels (Parmesan, Gruyère, Pecorino)

-

large cheddar blocks

-

semi-hard cheese in commercial shops

-

soft wheels that collapse under knives (brie, reblochon)

🏗 How It Works

The cheese wire cuts by tension-driven friction, not sharpness. When pulled with steady force:

-

Wire presses into the block

-

Pressure separates curd mass

-

No squeezing, tearing, or rind shock

This prevents:

-

deforming air pockets

-

rind crumbling

-

splitting along aging lines

📌 Primary Uses

Professional Uses

| Setting | Application |

|---|---|

| Cheese aging cellars | Cutting full wheels into sectors |

| Delis and markets | Portioning uniform slices for sale |

| Cheese factories | Precision cutting post-pressing |

| Catering & charcuterie | Clean presentation portions |

Home Uses

-

Cutting Gouda, aged cheddar, Manchego, gruyère wedges

-

Slicing soft rounds with no collapse

-

Clean cuts for cheese boards

🧱 Best Materials for Heavy-Duty Cheese Wire

Material determines hygiene, tension tolerance, and durability.

Preferred Wire Materials

| Material | Advantages |

|---|---|

| Stainless steel (304/316) | corrosion-proof, sanitary, long-lasting |

| Tensile-strength steel alloy | best for repeated high-pressure cuts |

| Food-grade braided steel | increased flexibility + no snapping |

| Titanium-coated steel | premium resistance to stretching & rust |

Avoid

-

raw iron (rust risk)

-

aluminum wires (bends & contaminates)

-

cheap carbon steel (snaps after repeated pulls)

Dairy law requires non-reactive metals to prevent acidity interaction with curd fat and salt.

🪚 Wire Thickness & Cut Quality

| Wire Type | Best Use | Cut Result |

|---|---|---|

| Thin tension wire | soft cheese, bloomy rind | ultraclean slice, no rind pull |

| Medium gauge | semi-hard cheese | controlled, smooth edges |

| Thick industrial | Parm/aged wheels | brute force cut without snapping |

For mixed-use home cutting, medium gauge is ideal.

⚙️ Handle & Frame Options

Wire Handle Designs

| Type | Benefit |

|---|---|

| T-grip stainless | strongest pull control |

| Loop handle | balanced tension |

| Dual-end frame | even slice thickness |

| Adjustable wire system | replaceable + consistent cut width |

If cutting wheels regularly, choose frame style to avoid hand strain.

🧴 Cleaning & Hygiene Care

Cheese carries fat, salt crystals, and microbial activity. Wire must remain sterile.

Daily Cleaning

-

Rinse in warm water

-

Mild, unscented detergent

-

Soft cloth wipe (avoid abrasives)

-

Dry after each slice during service to avoid buildup

Sanitizing

-

Hot water rinse at 80–90°C

-

Optional: food-grade sanitizer dip before cutting large volumes

Never leave wire soaking overnight—tension can weaken.

🔧 Maintenance Tips

-

Inspect for bends or micro-fraying

-

Replace wire at the first sign of rust, clouding, or stretch

-

Avoid twisting when pulling through hard cheese

-

Store flat or mounted, never coiled tightly

Replacement Cycle

| Environment | Frequency |

|---|---|

| Heavy commercial deli | every 2–6 weeks |

| Aging cellar cutting | every 1–2 months |

| Home use | every 3–6 months |

🛒 Buying Guide: What to Consider

Key Features

| Feature | Why It Matters |

|---|---|

| Food-grade steel | prevents contamination |

| Replaceable wire system | long-term cost savings |

| Ergonomic handle | reduces wrist pressure |

| Adjustable tension | consistent slice thickness |

| Non-slip grip | safety for aged wheels |

Recommended Dimensions

-

Length: 20–30 inches

-

Wire gauge: medium to heavy

-

Handle: T-bar or dual-frame

💰 Price Range

| Level | Price | User |

|---|---|---|

| Basic | $10–$25 | occasional home slicing |

| Mid-range | $30–$60 | home artisans & small delis |

| Premium commercial | $80–$200+ | affineurs & cheese merchants |

🌿 Eco & Safety Notes

-

Sustainable choice vs throwaway slicers

-

No plastic contact with live-rind cheese

-

Designed for hygiene compliance in dairy spaces

A wire never alters flavor because no blade oxidation touches the curd.

⭐ Conclusion

A heavy-duty cheese wire is the silent hero of cheesemaking and cheese service—ensuring uncompromised structure, clean cuts, consistent thickness, and pristine presentation.

From home charcuterie boards to professional aging caves, a strong cheese wire turns dairy into geometry: perfect wedges, unbroken paste, intact rinds, and slices fit for display. Durable materials, regular sanitizing, and smart handling extend its life and enhance safety. For anyone serious about cheese, this tool is indispensable.

FAQs – Heavy-Duty Cheese Wire

1. What makes a cheese wire “heavy-duty”?

Its tensile-strength steel, reinforced handle, and ability to slice dense aged wheels without snapping.

2. Can it cut soft cheese too?

Yes—thin gauge wires glide through soft, rind-bloomed wheels without collapse.

3. How often should the wire be replaced?

In commercial use every 4–8 weeks; at home every 3–6 months.

4. What material is safest?

304 or 316 stainless steel, or titanium-coated alloy.

5. Can it be used for other foods?

Yes, for butter blocks, terrines, soft pâtés—but avoid bones or frozen items.