Cheesemaking is both an art and a science, and the tools used play a major role in the final result. Among these tools, the rectangular cheese form (also called a rectangular cheese mold) is especially valued for its practicality, efficiency, and versatility. While round molds dominate traditional imagery, rectangular forms are widely used in modern artisan cheesemaking, commercial dairies, and home setups.

Rectangular cheese forms are designed to shape curds evenly, improve pressing efficiency, and create cheeses that are easy to store, slice, and package. This complete guide explores uses, materials, care, and buying considerations so you can confidently choose the right rectangular cheese form for your needs.

What Is a Rectangular Cheese Form?

A rectangular cheese form is a rigid mold used to shape cheese curds during draining and pressing. Unlike round molds, it produces block-shaped cheeses, which are ideal for slicing, stacking, aging, and commercial packaging.

These forms typically include:

-

Perforated sides for whey drainage

-

A matching follower (pressing plate)

-

Compatibility with manual or weighted presses

They are commonly used for semi-hard, hard, and some fresh cheeses.

Common Uses of Rectangular Cheese Forms

1. Efficient Cheesemaking

Rectangular molds allow curds to settle evenly, creating consistent density across the cheese. This improves texture and aging results.

2. Commercial Production

Block-shaped cheeses are easier to cut into uniform portions, vacuum seal, and ship. This makes rectangular forms popular in small dairies and large producers alike.

3. Home Cheesemaking

Home cheesemakers appreciate rectangular forms because they fit neatly into refrigerators, presses, and storage containers.

4. Specialty Cheese Styles

Rectangular forms are often used for:

-

Cheddar-style cheeses

-

Colby and Jack-style cheeses

-

Fresh pressed cheeses

-

Washed-curd and semi-hard varieties

Advantages of Rectangular Cheese Forms

Space Efficiency

Rectangular cheeses stack easily, maximizing storage space during aging.

Uniform Slicing

Straight edges allow for clean, even slices—ideal for retail and home use.

Better Pressing Control

Pressure is distributed evenly across flat surfaces, reducing cracks and air pockets.

Modern Presentation

Rectangular cheeses have a clean, contemporary appearance that appeals to today’s markets.

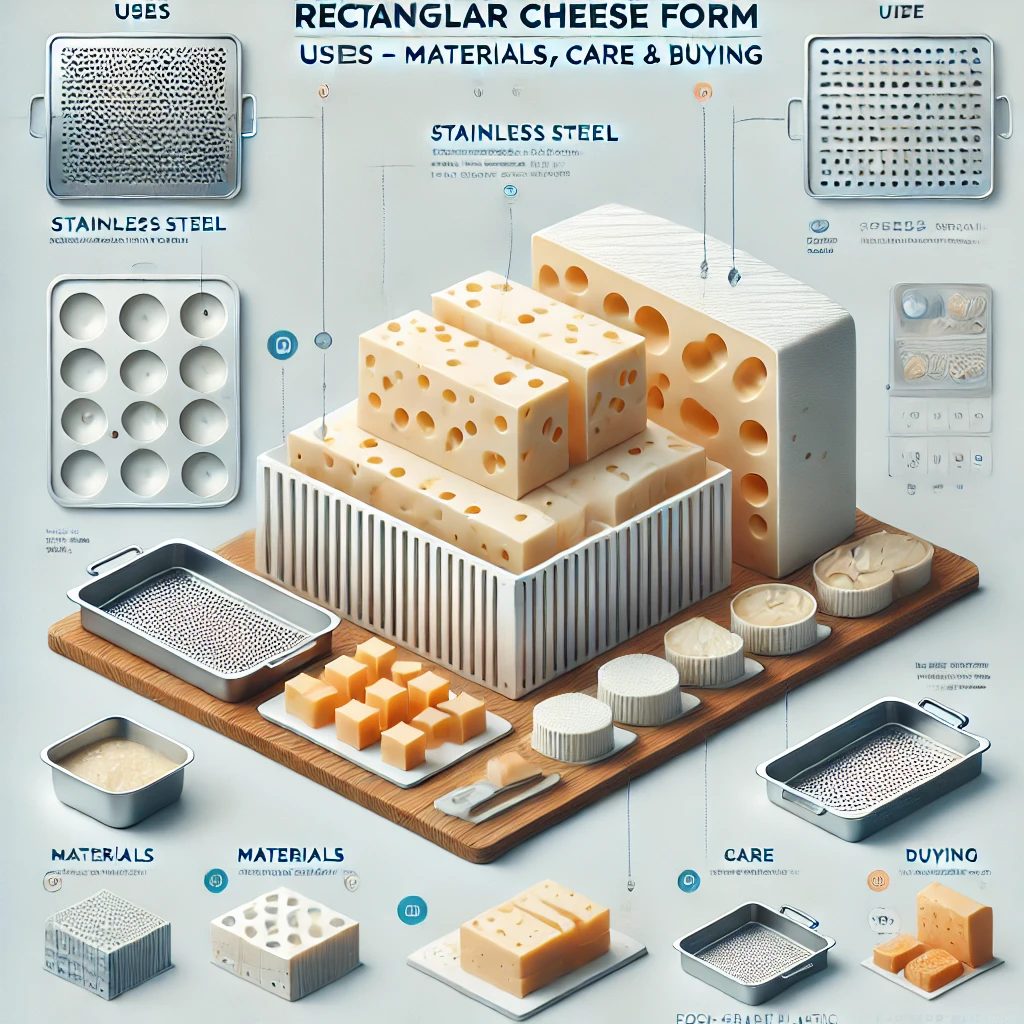

Materials Used in Rectangular Cheese Forms

Food-Grade Plastic

Most common and recommended

Pros:

-

Lightweight

-

Durable

-

Affordable

-

Easy to clean

Cons:

-

Can scratch over time

Ideal for beginners and professionals alike.

Stainless Steel

Professional-grade option

Pros:

-

Extremely durable

-

Fully non-reactive

-

Long lifespan

Cons:

-

Expensive

-

Heavier

Best for commercial dairies and serious cheesemakers.

Silicone (Less Common)

Pros:

-

Flexible

-

Easy release

Cons:

-

Limited support for pressing

-

Not ideal for hard cheeses

Better suited for soft or fresh cheeses.

Size and Capacity Options

Rectangular cheese forms come in various sizes, from small home molds to large industrial forms.

Common Capacities

-

Small: 500 g – 1 kg (home use)

-

Medium: 1–3 kg (artisan production)

-

Large: 3 kg+ (commercial use)

Always choose a form slightly larger than your expected cheese weight to allow proper drainage.

Drainage Design: Why It Matters

Good drainage is critical in cheesemaking.

Side Perforations

Allow whey to escape evenly during pressing.

Base Drainage

Some molds include slotted or perforated bases for faster whey release.

Liner Compatibility

Most rectangular forms work best with cheesecloth or reusable liners to prevent curds from sticking.

How to Use a Rectangular Cheese Form

-

Line the mold with cheesecloth

-

Fill with curds evenly

-

Fold cloth neatly over the top

-

Place follower on curds

-

Apply gradual pressure

-

Flip periodically for even shaping

Patience and even pressure are key to achieving a smooth, crack-free cheese.

Proper Care and Maintenance

Cleaning

-

Wash immediately after use

-

Use warm water and mild detergent

-

Avoid abrasive scrubbers

Sanitizing

-

Use food-safe sanitizing solutions when needed

-

Rinse thoroughly

Drying

-

Air dry completely before storage

-

Avoid stacking while wet

Storage

-

Store in a clean, dry place

-

Keep away from strong odors

Good care extends the life of your cheese form and prevents contamination.

Common Mistakes to Avoid

-

❌ Overfilling the mold

-

❌ Applying too much pressure too quickly

-

❌ Skipping the liner

-

❌ Poor cleaning between batches

Avoiding these mistakes improves cheese quality and tool longevity.

Rectangular vs Round Cheese Forms

| Feature | Rectangular Form | Round Form |

|---|---|---|

| Storage | Excellent | Moderate |

| Slicing | Very easy | Moderate |

| Traditional look | Modern | Classic |

| Pressing efficiency | High | High |

| Commercial use | Very common | Common |

Rectangular forms are often preferred for practicality, while round forms appeal to tradition.

Who Should Use Rectangular Cheese Forms?

-

Home cheesemakers

-

Artisan producers

-

Commercial dairies

-

Culinary schools

-

Cheese experimentation labs

Anyone making pressed cheese regularly benefits from rectangular forms.

Buying Guide: How to Choose the Right Rectangular Cheese Form

1. Cheese Type

Hard and semi-hard cheeses require rigid molds with good drainage.

2. Production Scale

Choose capacity based on batch size and future growth.

3. Material Preference

Plastic for affordability, stainless steel for longevity.

4. Press Compatibility

Ensure the mold fits your cheese press dimensions.

5. Ease of Cleaning

Smooth interiors and rounded corners simplify maintenance.

Price Range and Value

-

Plastic molds: Affordable, great value

-

Stainless steel molds: Higher upfront cost, long-term investment

Buying quality once often saves money over time.

Sustainability Considerations

Durable cheese forms reduce waste by lasting many years. Reusable liners and proper maintenance further improve sustainability in cheesemaking.

Why Rectangular Cheese Forms Are a Smart Choice

Rectangular cheese forms combine efficiency, consistency, and modern practicality. They simplify pressing, storage, slicing, and presentation—making them one of the most versatile tools in cheesemaking.

Whether you’re crafting cheese at home or producing for sale, this mold shape supports both creativity and reliability.

Conclusion

A rectangular cheese form is more than a mold—it’s a foundational cheesemaking tool. By understanding its uses, materials, care, and buying considerations, you can elevate both the quality and efficiency of your cheese production.

From home kitchens to professional dairies, rectangular cheese forms continue to prove their value through consistency, practicality, and timeless utility.

FAQ: Rectangular Cheese Form Guide

What is a rectangular cheese form used for?

It is used to shape and press cheese into block form during cheesemaking.

Are rectangular cheese forms better than round ones?

They are more efficient for storage and slicing, though both have valid uses.

What material is best for a cheese form?

Food-grade plastic is best for most users; stainless steel is ideal for professionals.

Do I need a liner with a rectangular cheese form?

Yes, cheesecloth or liners help prevent sticking and ensure clean removal.

How long does a cheese form last?

With proper care, a high-quality cheese form can last many years.