Rectangular Block Cheese

Definition and Scope

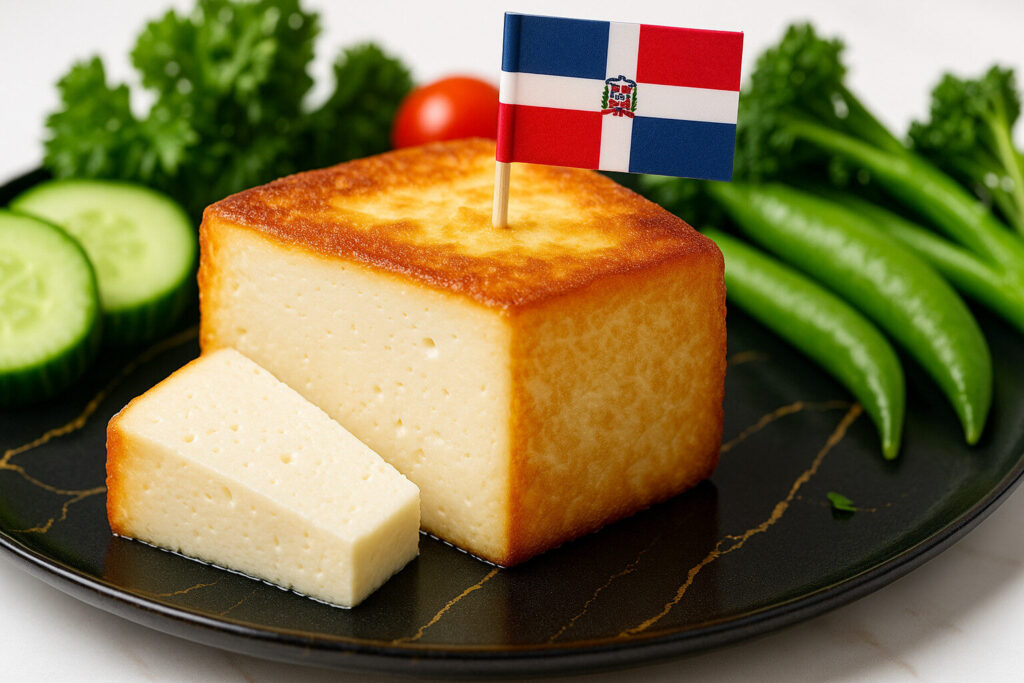

Rectangular block cheese refers to cheeses formed into uniform rectangular prisms during production. This standardized shape facilitates efficient packaging, transportation, and slicing for retail and food service. The category includes numerous cheese varieties, from mild cheddars to provolone, primarily defined by their geometric form rather than a specific milk type or aging process.

This format dominates industrial cheese production, particularly in North America and Europe, for its logistical advantages. Blocks typically range from one to forty pounds, with dimensions optimized for machinery like slicers and graters. The form allows for consistent quality control and portioning, making it a staple in supermarkets and commercial kitchens worldwide.

Production Process

Manufacturers create rectangular blocks by pressing curds into lined molds under controlled pressure and temperature. The cheese then undergoes brining or dry salting before aging in climate-controlled environments. This method ensures even moisture distribution and structural integrity throughout the block.

Industrial production often employs block-forming towers that continuously fill and press curds into rectangular shapes. After demolding, the blocks are vacuum-sealed in plastic to prevent moisture loss and microbial contamination. Aging periods vary from weeks for fresh cheeses to over a year for aged varieties like Gouda or Parmesan.

Sensory Profile

Rectangular block cheeses exhibit diverse sensory characteristics depending on their variety. Mild cheddar blocks typically offer a smooth, creamy texture with subtle tanginess, while aged Gruyère develops crystalline crunch and nutty complexity. The form itself doesn’t determine flavor but allows consistent flavor development throughout the cheese.

Texture ranges from semi-soft Monterey Jack to firm Emmental, with color varying from pale white to deep yellow. The block shape ensures uniform flavor distribution without rind influence, as most retail blocks have surface coatings removed. This consistency makes them reliable ingredients for cooking and direct consumption.

Culinary Applications

Rectangular blocks are ideal for mechanical slicing and shredding, making them preferred for sandwiches, pizzas, and processed cheese products. Their uniform dimensions allow precise portion control in food service and manufacturing. Many blocks are specifically designed for melting properties in cooked dishes.

Home cooks value block cheese for its versatility in grating over pasta, cubing for salads, or slicing for charcuterie boards. The form protects the interior cheese from oxidation and flavor loss until opening. Food manufacturers use bulk blocks as base ingredients for cheese sauces, frozen foods, and ready meals.

Regional Examples

Wisconsin produces vast quantities of rectangular block cheddar and Colby, typically aging them for 3-12 months. These American classics feature firm, smooth textures and range from mild to sharp flavors. Their standardized 40-pound blocks are industry benchmarks for quality and consistency.

European examples include Dutch Gouda blocks with their characteristic yellow wax coating and Swiss Emmental in 200-pound blocks. The United Kingdom exports rectangular block Double Gloucester, while Italy produces Parmigiano-Reggiano in smaller 66-pound blocks. These regional specialties maintain traditional flavors while adapting to modern distribution requirements.