Wheel Form Cheese

Definition and Scope

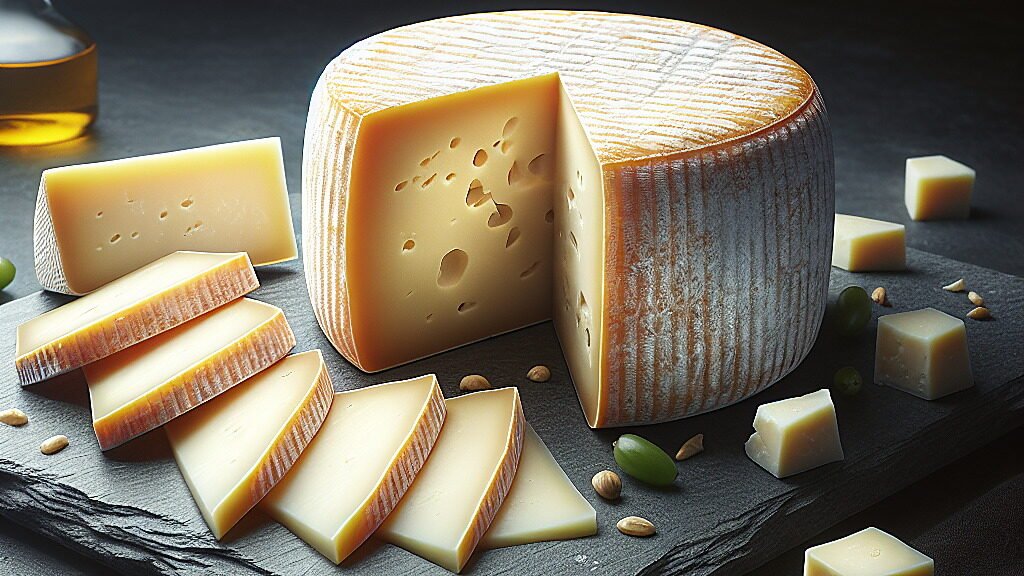

Wheel form refers to cheeses shaped into round, flattened cylinders during production. This traditional shape facilitates even aging and rind development across the cheese surface. The form is common across many cheese styles, from hard aged varieties to softer surface-ripened types.

Wheel sizes range dramatically from small individual portions to massive wheels exceeding 100 pounds. The form’s dimensions directly impact aging dynamics, with larger wheels maturing more slowly than smaller ones. This shape remains one of the most recognizable and practical in global cheesemaking traditions.

Production Process

Cheese wheels form when curds are packed into circular molds that determine the final diameter and height. Pressure application during molding expels whey and consolidates the curd mass into a cohesive unit. The specific mold type and pressure level vary according to the cheese style being produced.

After unmolding, wheels typically undergo brining or dry salting to form a protective rind. They then enter aging facilities where they are regularly turned to maintain shape and ensure uniform moisture distribution. This turning process prevents deformation and promotes consistent texture development throughout the wheel.

Sensory Profile

The wheel form contributes to distinctive sensory characteristics through its impact on aging dynamics. Larger wheels develop more complex flavor profiles due to extended, gradual moisture loss and enzymatic activity. The shape promotes even rind development, which influences both flavor and texture progression.

Texture often varies from the wheel’s exterior to its center, creating a gradient of sensory experiences. The protective rind that forms on the wheel’s surface helps retain moisture internally while allowing controlled evaporation. This results in concentrated flavors and firm textures that distinguish wheel-formed cheeses.

Culinary Applications

Whole cheese wheels serve as dramatic presentation pieces for tableside service and special occasions. Restaurants frequently purchase entire wheels for portioning consistency and waste reduction. The form allows for controlled aging until the moment of serving, ensuring peak flavor development.

In retail, wheels provide merchants flexibility in cutting custom portions for customers. The intact wheel protects the cheese’s interior from oxidation and moisture loss until cutting. Many traditional recipes specifically call for wheel-formed cheeses to achieve authentic texture and melting properties.

Regional Examples

Parmigiano-Reggiano represents the classic Italian wheel form, with massive 80-pound wheels aged for extended periods. These wheels feature distinctive pin-dot markings and stamped rinds that guarantee authenticity. The form is essential to developing the cheese’s characteristic granular texture and complex nutty flavor.

French Comté wheels typically weigh around 80 pounds and display a natural grayish-brown rind. Swiss Emmentaler forms large wheels distinguished by their smooth, firm rinds and iconic holes. English Cheddar traditionally forms smaller cloth-bound wheels that develop characteristic earthy flavors during aging.